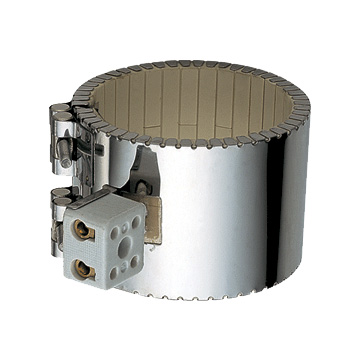

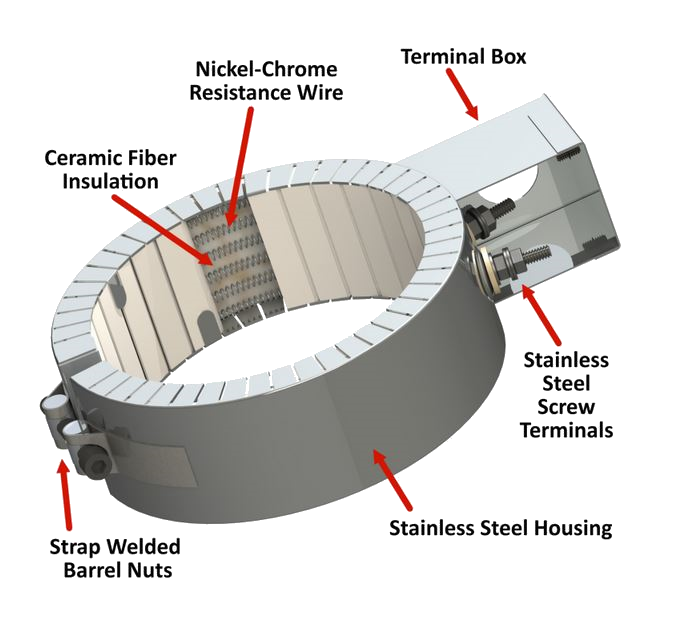

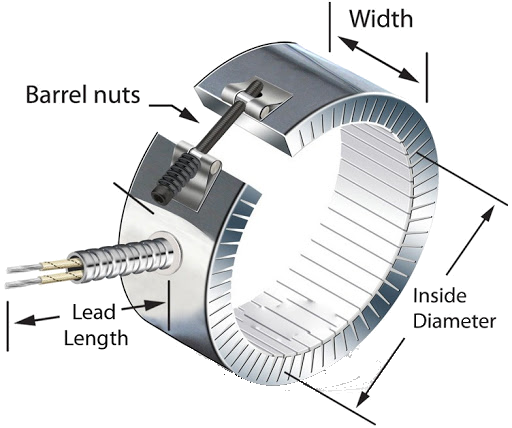

Ceramic band heaters are designed with spirally wound inner resistance coils stretch and strung evenly threaded through the interlocking insulated ceramic. The ceramic core is housed beneath a stainless steel sheet with serrated edges. This combined assembly of the Ceramic Band Heater offers a flexible heating system that works as an efficient transmission of conduction and radiated heat. The heat of the Ceramic Band originates from the inner coils that transfer heat through conduction. Fitment of the heater is the most important parameter of the ceramic bend heaters.

As you know AMEE stands for the reliability and quality. As we have developed ceramic band heater up to 1200 mm of diameter and 750 mm in length, Also we have the expertise to compensate Maximum 3 numbers of sensors Holes in single barrel heater along with Junction box. Our premium quality of ceramic heater comes with the special feature of cost-saving up-to 25% with Heat Loss, for that we have optional attachment cover of Insulation Jackets on the otter side of ceramic band heater, that drastically reduces radiant heater loss. It indirectly saves more than 25% of electricity. Our motto is to understand customer’s needs and provide optimum products that are not only cost-effective but also a durable life. As we have almost all types of heaters production and testing in-house facility, so we are consistent and leader in the heater market. We serve the OEM’s for more than two decades.

- Round Shape

- Diameter range: 30 mm to 1200 mm

- Width/Height range: 25 mm to 750 mm

- Half Round Shape

- Square Shape

- Flat type

- With Heat Saving Insulation Jacket (optional feature)

- With Air Cooling arrangements to maintain temperature within the narrow range for specific critical product- this helps in excellent product quality

- Sensor Hole: Maximum 3 hole can be compensated in single heater

- Our expertise is to design heater suitable for the supply voltage range from 12 vdc, 24 vdc, 110V,1 phase , 2 phase & 3 phase

- Terminal type we offer:

- Ceramic Type

- Wire/Cable leads

- Teflon insulated Cable

- Fiber glass insulated cable

- Silicon insulated Cable

- SS Braided two or three core fiber glass cable

- Brass terminals: SS/Brass

- Iron connector socket

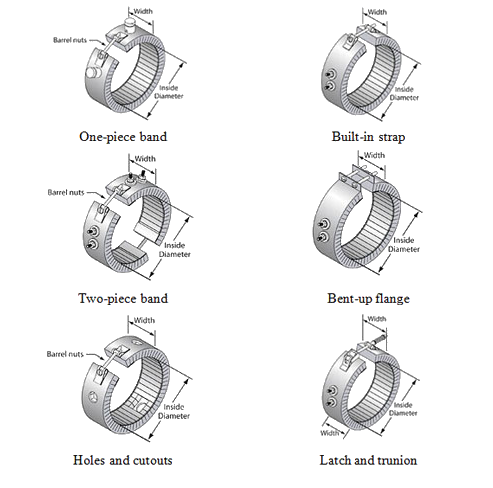

- Clamping type we offers

- Flange lockup

- Latch and Trunion

- Barrel Nut Lock-up

- Excellent dielectric strength at high temperatures with high voltages

- Ability to interlock and provide a more rigid structure

- Reduces the chances of damaging internal coils in transit and handling

- Allows for easier installation of the heater onto the Barrel

- High tension expansion spring on the clamping for tighten fitting over the barrel

- Longer Heater Life and High performance

- Minimum Heat loss and Maximum Heat transfer

- Uniform temperature around the Barrel

- Flexible i.e. easy Installation and Maintenance

- Variety of it can be made according to different diameters and heights

- Lower Operating Cost

- Blow Molding

- Die Heads

- Extruders

- Heating Pipes

- Injection Molding Machine

- Plastic Blow Molding Machine

- Rubber and Plastic Extruder / Extrusion Process

- Nozzle Heaters with small variety of ceramic

- Internal Diameter of the Heater or outer Diameter of Barrel

- Height/Width of the Heater

- Heat Load (KW)

- Input Voltage

- Type of the Terminal required

- Type of Clamping

- Number of Sensor Holes and it’s Diameter

- Sensor Holes Position/Location in heater

- Terminal Position

- With/Without Energy Saving Insulation

- Insulation thickness or jacket thickness

- Type of medium to be heated

- Temperature Range

Send us an inquiry